Ishii Pulsar Pump

Energy & labor saving pump system

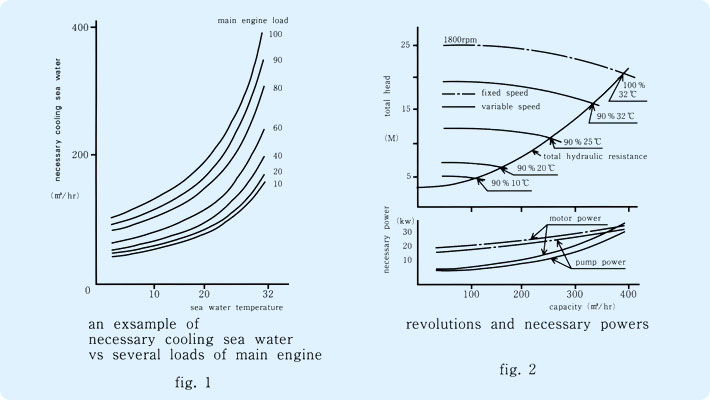

The head and capacity of cooling sea water pump for marine Diesel engine is planned under the conditionns that at Maximum continuous running, the pump is able to cool the engine with sea water at 32℃, namely at the Persia gulf condition.

As you know, the temperature of sea water differs very much depending on the route of voyage. For example near 0℃ at the winter north Atlantic Ocean. It means in many cases, a lot of water is by−passed and wasted to avoid over cooling. Fig 1 shows an example.

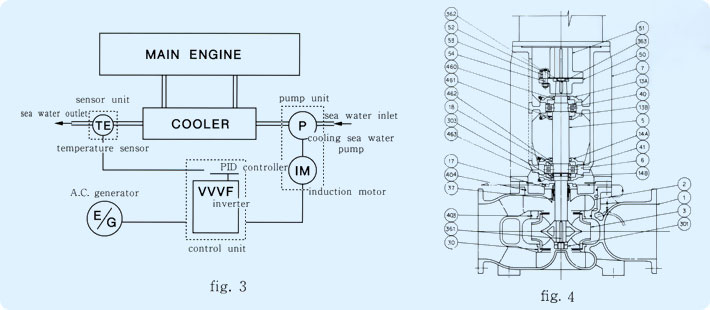

Meanwhile, the necessary power for the pump is proportional to the third power of the revolution. Therefore, it is a great saving of the energy, if the revolution is so controlled that necessary cooling water flows. Fig 2 shows capacity−power performance when revolution is varied.

Other energy saving method, such as pole change method is of limited effect and eddy current coupling control method is of high cost with less energy saving. Comparing with above, our system, consisted of high efficiency inverter control and maintenance free Poseidon Mark3, succeeds both large energy and labor savlng with reasonable cost.

The outline of the system

Fig 3 shows schematic diagram of the system

The system is consisted of

- Pumplng unit

1. Poseidon Mark 3 vertical centrifugal pump

2. 3 Phase A. C. induction motor - Control unit

3. VVVF type inverter

4. PID controller - Sensor unit

5. Sea water temperature sensor

The temperature sensor fitted at the adequate outlet point of cooling

sea water pipe line, takes sea water temperature.

PID controller regulate the pump revolution completely continuously in

order to accord real sea water temperature to the previously set temperature.

The advantages of the system

- The pump : Poseidon Mark 3 vertical centrifugal type is of high efficiency, of long life, of short time and easy overhauling and reassembling. Fig 4 shows the sectional arrengement.

- Newly developed VVVF type inverter enables perfectly continuous revolution

control.

It is of high efficiency, of high reliability and of long life. - Small overhauling space for the pump and small inverter enable compact and small space system.

Example of energy saving

In case of 13,000 HP Diesel Engine of normal running and cooling sea water pump of

800m3 / hr × 18m × 1800min-1 × 50KW

Running condition

Sea water temperature 20℃

85% of max cont. running condition.

| Necessary sea water capacity | 40% of planned condition. |

| Revolution | 70% of planned RPM. |

Necessary power 19KW

Saving is 31KW

If 250 voyage days per years, the a heavy oil saving is about 35TONs per

year.